Chapter I: Soundproofing the shared wall

One of my main concerns when I started thinking about building a golf sim was noise. First up, I don’t want to annoy my partner with the constant noise, but also I live in a side-by-side duplex and I don’t want to annoy my neighbors. The worst thing that could happen is that I invest a lot of money into a golf sim and then I can’t use it because of noise complaints.

Research and Design Decisions

The room shares a wall with the neighboring unit. The other walls are two outside walls and one internal wall. In general, the house is not super well soundproofed. Our neighbors have a teenage kid and when they play loud music, you can hear it all over the house. The biggest offender here is the shared brick wall which resonates the sound all over the house. Naturally this wall was my biggest concern, coincindetally it’s also the wall that I’d be hitting against. Well, not directly, of course, but it’s the wall where I’d mount the impact screen in front of.

I decided to go with a drywall setup with 100mm (4") of stone wool insulation and a single-layer of 12.5mm (1/2") drywall. Putting such a setup in front of an existing wall is fairly common here in Germany for soundproofing. To my delight, Knauf, one of the manufactures of drywall equipment published a super detailed guide on exactly how much sound dampening you can expect from each setup. I decided to go with W625.de with 100mm studs and 100mm of stone wool.

Alternatives Considered

-

Using two layers of drywall instead of one: Most guides recommend two layers of drywall. However, a setup with 75mm (3") studs and two layers would have only given me a 3dB improvement. (17dB vs 14dB). I decided that the extra cost and effort wasn’t worth it. If I’m wrong, I can always add a second layer later.

-

Not using any drywall, but instead going with a high-density foam. It’s hard to compare exactly how thick the foam would have had to be to achieve the same level of soundproofing – because I couldn’t find any scientificly accurate data. In fact, the only content I found on using foam was from companies that sell foam. A rough guesstimate is that an equivalent foam setup would have cost twice as much and I would not have been able to buy the materials at a local hardware store. For the drywall setup, I could get every single item listed in the Knauf guide at my fairly mediocre, but very close by, hardware store.

The build

Prep

First up, I had to remove the baseboards and cut out about 12cm (5") of the hardwood floor. That was fairly easy using a circular saw that I already had. I did, however, forget to take into account that the circular saw can’t reach all the way to the edges. I tried to use a handsaw, but it couldn’t get through the hardwood. I ended up going to the store again and picking up one of those oscillating saws. That worked like a charm.

Test fitting the bottom plate. What you can’t see here is that there is a layer of sealing tape on the bottom. This prevents coupling our wall with the existing walls, floor, and ceiling.

Framing

Once the bottom plate was fastened, I decided to build a temporary construction with a few studs to hold the top plate in place. I have no idea if this is how this is typically done, but it worked like a charm. Once up, I used a level to make sure the studs were straight and put some cardboard behind the top plate to keep the right distance from the existing wall.

Temporary construction to hold up the top plate. This worked really well.

Once the top plate is fastened to the ceiling, placing the studs is very straight-forward.

Insulation

So, here is where it gets weird. The standard distance between studs in Germany is 625mm (24.6"). That’s why the stone wool comes in 625mm. However, for whatever reason all the drywall boards you can buy at DIY stores come in 600mm (23.6") width. I have absolutely no idea why that is, but I find it very confusing. I ended up placing the studs 600mm apart and cutting the stone wool to 600mm. That added one more step, but wasn’t the end of the world.

Not pretty, but it’ll do.

Drywall & Mudding

Nothing to say here really. I once made a wrong cut and then couldn’t use a piece which is why there are three boards in one of the columns. Not the end of the world, I guess.

End of day 1: The drywall is mounted.

The next morning I applied the mudding. Pretty obvious here that this was my first time. It looks fairly chaotic, but honestly, it’s smoother than I thought it was going to be. Not that it matters, really, there will be an impact screen in front of this wall anyway.

Results: Is it working?

It’s a bit hard to tell at this point because the door is by far the weakest link right now. So, any sound coming from the room is currently audible in the rest of the house. There is one very positive sign though: Just when I was done this morning, the neighbors started playing fairly loud music. I could hear it, but it only came in through the side walls. Putting my ears against the new wall, I couldn’t hear a thing. That does however raise the question whether I will still have to do something about the side walls. I’ll have to wait and see.

Mistakes made and lessons learned.

When they say you should cover your entire skin when working with stone wool, they’re probably right. After a few minutes I started to improvise and taped my shirt to my gloves.

You really don’t want to leave any skin exposed on your arms when working with stone wool.

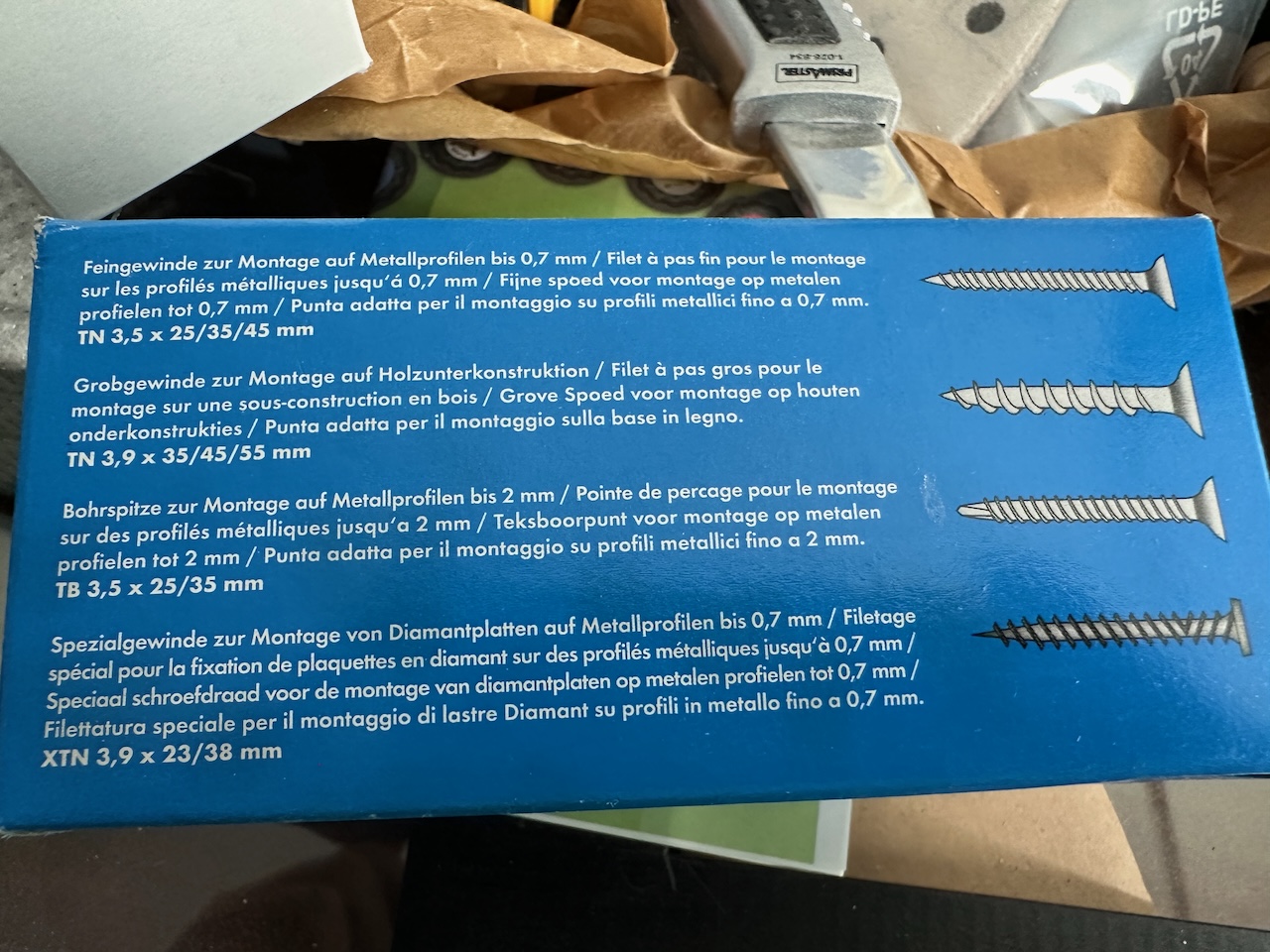

I used the Knauf diamond board because that’s supposedly better for sound proofing. However, I had no idea that you’re supposed to use different screws for this one. The regular ones were a bit hard to get flush with the board. For this wall, it doesn’t matter, but if this was a wall that was going to be painted, it might have been a problem.

Apparently, theres a specific type of screw for this type of drywall board. I used the first option, but the fourth would have been the right type.

Next steps

- Soundproof the door.

- Figure out if I need to do something about the sidewalls. If so, it’ll probably be a simpler setup. Maybe just some high-density foam.

- Figure out the dimensions for the impact screen, decide on a specific product, and order it.