Chapter III: The impact screen - Fail fast and often

In software engineering, there’s a concept called “fail fast”. The idea is to quickly identify issues and address them before they become a bigger problem. Essentially, the goal is fast iteration. Let me tell you, I have certainly failed fast and often in this chapter of the project.

Choosing an impact screen

I knew that I was going to go with a high-quality impact screen. You can get some fairly cheap ones, but they are usually made from a single layer of fabric. This is not only bad for the longevity of the screen, but also for the sound dampening. I wanted a screen that would last and that would dampen the sound of the ball hitting it. So, I knew it was going to be a 2 or 3-layer screen.

That also meant that there weren’t too many options here in Germany. It basically came down to the following options:

- Try and find a vendor within the EU, so I wouldn’t have to pay import taxes

- Order from the well-known shops in the US, such as Carl’s Place and pay huge shipping fees in addition to the import taxes

- Order from the UK, which would make shipping a bit cheaper, but – thanks to Brexit – I would still have to pay import taxes

Luckily, YouTube came to the rescue and I saw a video from Handicap Golf that was sponsored by a company called Golfroom.eu. They are based in Lithuania, so no import taxes. I went to their website and saw two things that I really liked:

- They were really proud of the quality of their screens and even offered to send out free samples

- They had no extra charge for custom sizes, so I could get a screen that would fit my setup perfectly

The screen also looked great in the sponsored video, so I decided to order the sample right away. It has another advantage, which I will tell you about in a future post.

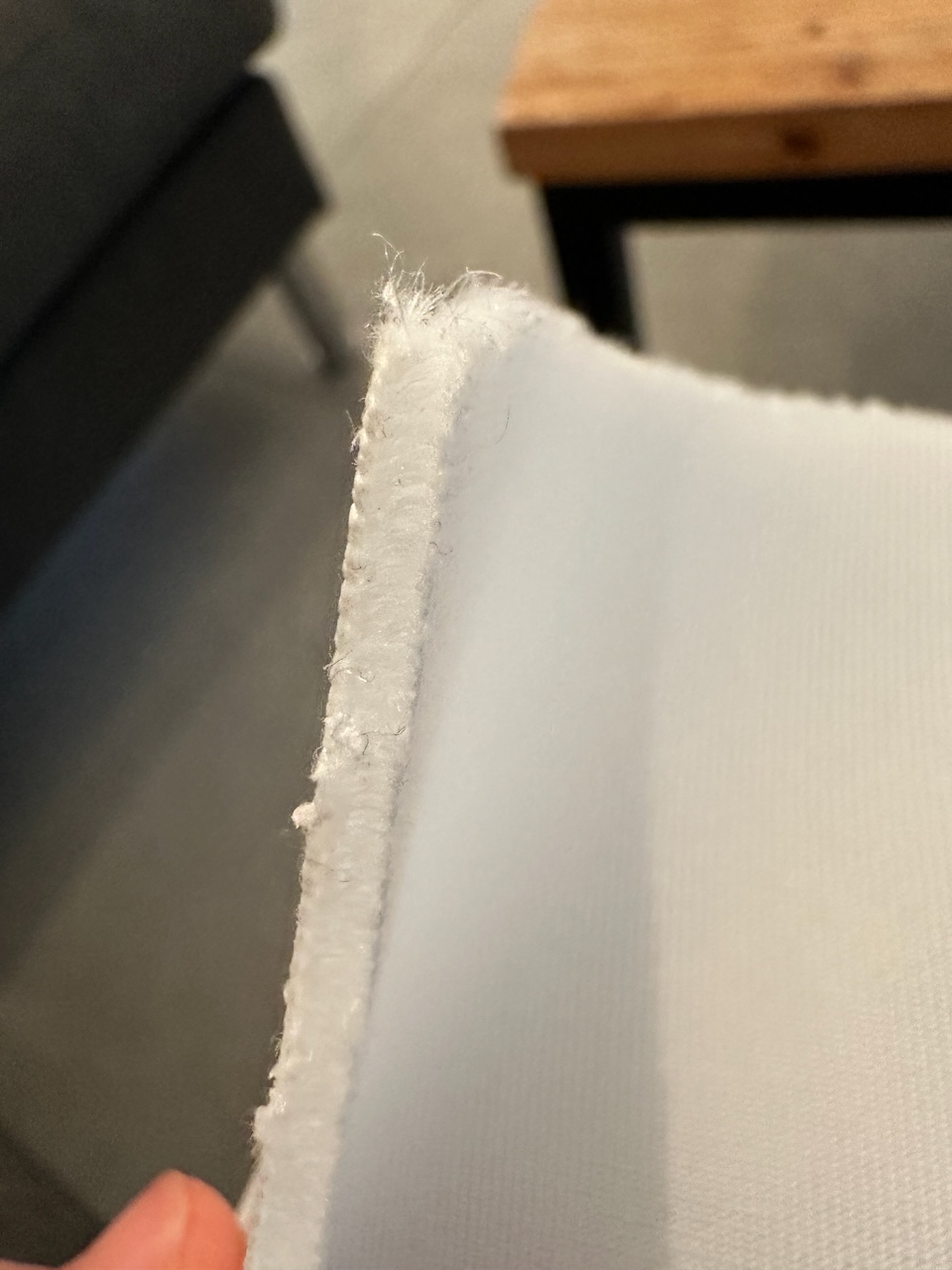

The sample took a few days to arrive from Lithuania, but it confirmed the quality. The 3 layers are clearly visible. Essentially a foam layer sandwiched by two net layers. Overall the fabric also seemed very sturdy and yet a bit elastic. I was convinced.

Impact screen design parameters

So far, so good, but I promised you some (fast) failures, so here we go. The same video I mentioned above also had a few comments about how people typically mount the impact screen. One person said that – despite the official recommendation to hang it about 30cm (12") from the wall – they had mounted it just 15cm (6") from the wall and it worked fine. This was great news for me, because I didn’t want to lose any more space in the room.

I also thought that I might pad the wall with some foam, so that if the ball was not stopped by the screen in time, it would hit the foam and not the wall.

The same YouTuber recommended mounting metal profiles to the wall and ceiling and attaching the screen to these profiles using either cable ties or elastic rope. With that in mind, I came up with the following design dimensions:

- Screen Dimensions: 3.5m x 2.4m (11'6" x 7'10"). Note this is no standard aspect ratio, it is not high enough for 4:3 and not wide enough for 16:9. But that is fine, I can always project a smaller image.)

- Screen mounted: 20cm (8") from the wall

- Foam padding: 7cm (3") thick, this left the screen about 13cm (5") of travel and then another 7cm to stop the ball from hitting the wall.

- Metal profiles: 23mm x 23mm (1" x 1") L-profiles made of stainless steel

The first setback – was the foam a bad idea?

I started fitting the foam panels to the wall. This looks a bit chaotic, because I wanted to maximize the use of the foam panels, which required quite some cutting. But I was happy with it – no one would ever see this behind the impact screen anyway.

The very first panel fitted. All panels fitted The L-profiles are fitted to the wall and ceiling. I believe they were originally meant for shelf construction, which is why I trust that they are strong enough. Also, they came with holes in a regular and frequent spacing, which made it easy to attach the screen.

Once the impact screen arrived, I started test fitting it.

Putting up the impact screen is easy once everything else is installed. I used cable ties as recommended in the video.

Here’s where it started going south. Now that I had an impact screen, I could try hitting some balls. Admittedly, I didn’t even have a hitting mat yet, so I just hit some balls off a random piece of foam. But it was enough to see that the current setup wasn’t going to work. With the reduced travel of the screen and the foam padding, the whole setup was so incredibly bouncy that even a chippy pitching wedge would bounce off the screen so hard it would fly all over the room. A particularly high shot could easily hit me on the head, so this whole setup wasn’t going to work.

In addition, the impact screen hitting the foam padding was also quite loud – at least inside the room. I abandoned the idea pretty quickly again. Nevertheless, I wanted to leave some foam padding around the edges to stop stray balls from embedding themselves in the drywall. This may or may not have happened once during testing. 😇

Here you can see me remove the impact screen and take out some of the foam panels. I removed a bit more foam later to make sure the hitting area was clear.

The next setback – that doesn’t look right

In the midst of all of this, I started noticing that something was off. The metal profile to the right side of the screen had come off the wall. I had used some fairly cheap screws and wall anchors, and also not enough of them.

If this is what it looks like after a few test shots, how is this thing supposed to handle thousands of hooks and slices a week?

I had realized the key mistake. The left wall is an exterior wall. Since this is a basement room, it’s made of solid concrete. The ceiling is also concrete. The right wall, however, is made of hollow clay bricks. The wall anchors were likely not long enough to create enough friction.

I decided to get better ones. They were rated for about 135kg (300lbs) each in concrete and at least still around 35kg (80lbs) in hollow bricks. I also used more of them.

These guys won’t come off again. At least not until I can reach 200mph ball speed – which is not planned for the next decade

Because I had to remove the foam, I also no longer felt confident in my idea to shorten the travel distance from 30cm to 20cm. So I decided to go with the manufacturer’s recommendation and put the new profiles 30cm from the wall. I did not remove the old ones (where they hadn’t failed), so in some of the following pics you can see both setups. I thought that might give me some flexibility in case I changed my mind again.

Third time’s the charm – what about that hardwood floor?

At this point, the room still had its original hardwood floor. Or rather, a composite floor with a hardwood layer glued onto cheaper wood. Originally, I wasn’t sure if it should stay or go. However, now that the impact screen was working again, I could do some more testing. And it didn’t take long until I got some feedback from my partner that the setup was a lot louder than planned. Not just impact itself, but even just the ball bouncing on the floor. Note that I already had gym mats placed along the floor, so it’s not like the ball ever hit the hardwood floor directly. But it seems that the sound was still transmitted quite well.

My partner said this particular room had always had a very loud floor; we should just rip it out. I was glad that she suggested that, because now I didn’t have to bring it up. She was even willing to help. 😍

Starting with the first corner. This stuff started piling up quickly. Wow, this looks quite clean for the first time.

To my delight, this really helped. While tearing out the floor, I also noticed that the floor was directly touching all four walls in many places. That likely contributed to it being so loud. It was never correctly decoupled from the side-walls and just transmitted all the sound. I’m glad I got rid of it.

Chapter III - Conclusion

All that was planned for this chapter was to choose and install the impact screen. But there were so many ups and downs that I almost doubted the project’s feasibility at some point. But now, with the floor gone and the impact screen fitted again, I’m more confident than ever. It’s also starting to look really nice.

The impact screen in its final position. This took quite some iteration to get here.

After I took the picture above, I made a few more slight alterations. I played around with the tension of the screen. In the picture it is a bit tighter than what it is right now. Big shoutout here also to Tomas from golfroom.eu who is extremely helpful and responsive.

Next steps (in no particular order)

- Framing the screen with surrounds to make it look more professional

- Tech setup: Launch monitor, projector, and gaming computer

- Side wall covering (visuals, sound dampening inside the room, catching stray balls)

- Artificial turf, hitting mat, and general floor covering

Disclaimer: I have mentioned quite a few products and companies in this post. I have no affiliation with any of them other than being a satisfied customer. I was not asked to name any of them, I’m doing this at my own choice. There are no affiliate links in this post as of now (this could change in the future).