Chapter II: A more soundproof door

Last week I showed you how I sound-proofed a wall that’s shared with the neighboring unit. After the project was complete, I stated it’s hard to tell how much of an improvement it made because the door was now the weakest link.

To no one’s surprise, this week’s project was to tackle the door. In fact, this project started in parallel with the wall project. This is because I wasn’t sure whether I would buid the wall with drywall and stone wool or with foam. Drywall was never really an option for the door, so I ordered some foam panels. That was meant to improve the door, but also to give me some experience with foam before I decided on the wall.

The foam was delivered fairly late, and I didn’t want to wait with the wall, so I went ahead with the drywall. When the foam finally arrived this week, I got some immediate confirmation that this was the right decision.

The door design kept evolving throughout the project

My initial plan was simple. I wanted to glue the foam panels to the hollow-core door and that was supposed to be it. However, when the panels arrived, I did some simple very non-scientific tests. I played loud music on my phone and sandwiched it in between two 8cm (~3") foam boards. While this did reduce the sound somewhat, it was fairly disappointing. Especially considering that I had paid around 170€ for the foam needed for the door. The entire wall cost only around 500€.

When I researched the wall, I came across the concept of the mass-spring-mass system where you essentially have a sandwhich of two masses with some sort of a “spring” in between. In case of the drywall, one of the masses is the existing wall, the spring is the rock wool and the other mass is the drywall.

Having that in mind, I extended my unscientific test. I put a leftover piece of drywall on top of the phone. To my surprise, the sound was reduced very significantly.

I didn’t think that I could mount drywall to the door, so I went to the hardware store and got some OSB. With the boards being significantly lighter than drywall, the dampening effect was less pronounced. But it was still so much better than just the foam. So, I decided to go with a foam-OSB sandwich.

Starting the build

My weapon of choice was this cheap dive saw that I already had. A table saw would have probably made this a lot easier. But with a lot of measuring and clamping this was achievable.

My idea was two build a 3-sided enclousure around the foam and then fasten this to the door. The door itself is wider than a single OSB board, so I cut two boards to size and glued them together. Then I cut 8cm (~3") side walls from the remaining OSB sheet.

You can see the general idea here. The OSB enclosure to hold the foam boards.

I left some space for the door knob which I then later cut out of the OSB with a jigsaw

Originally, my plan was to just glue everything together. Glue the wood to the foam and then glue the entire thing to the door. But, when I saw the amount of force required when clamping everything together, I lost trust that glue is enough.

One of the reasons why I wanted to avoid screws initially was that I wanted to paint the door. But then I had the idea that I could also glue some foil on it which would hide the screws. So, I went back to the store, picked up some screws and the foil and screwed everything together. Given how heavy the entire door is (Rough guesstimate around 35kg (77lbs)), I’m glad I did that.

When I took this picture, I started with leftover drywall screws, but then I went and got some longer, thicker screws. I’m glad I did.

That was the moment to test the door. And I did, you’ll see the results below, but first let’s finish the build.

A quick sand job before aplying the foil to make sure it’s as smooth as possible. Which is not very smooth with OSB…

Here’s the door with the foil applied to it. I was positively surprised at this step, but as you will see below, this is door is not finished just yet!

While the foil alone already looked so much better than raw, exposed OSB would have, I had one more trick up my sleeve. I fastened some black accoustic foam panels to the door. This should serve two purposes:

- The door has a fairly flat surface which is not ideal for echo in the room. The foam should help with that.

- It really helps to hide some of the imperfections ;-)

I really like the look of the brick wall pattern. As I’m typing this the next morning, two panels have already fallen off, so I guess I’ll have to revisit that.

Before and After – how good is the door now?

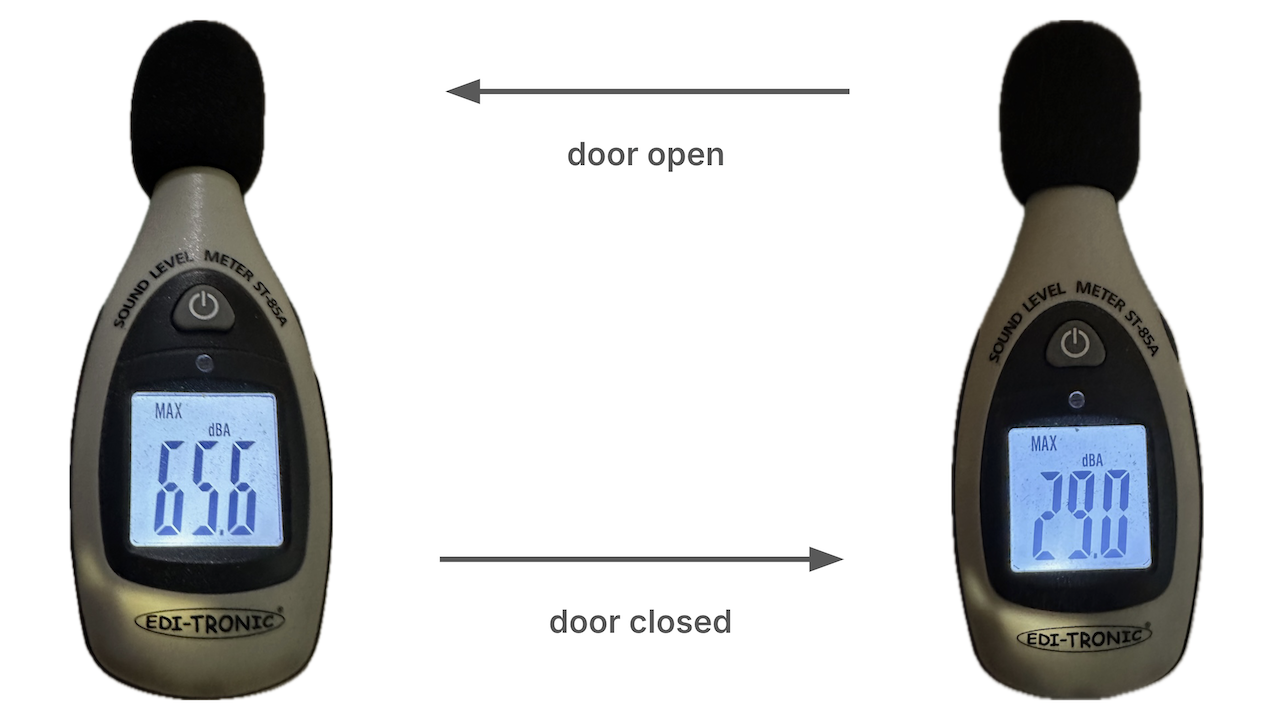

Time for one last unscientific test. This time I played “Can’t stop” by the Red Hot Chili Peppers on my iPad on full volume and measured the noise level right outside the door. The difference between having the door open vs closed is very significant now. You can still hear some music, but it’s not crazy loud. A very unscientifically measured reduction of ~30-35dBA sounds good to me. Definitely much better than what the hollow core door could do.

Big difference now between an open and closed door: Peaks of 65dBA vs 29dBA

Shortcuts taken, Mistakes made, and lessons learned.

There were too many mistakes made to count, mostly small errors when cutting the OSB. Part of it, is that cutting exact measurements with a dive saw and only a long level is really hard. The other part is probably my lack of experience. But none of that kept me from building something that works.

I also took some shortcuts. For example, the 3-sided enclusure essentially means that the inner wall now has a direct connection to the outer wall. It is not decoupled, I could have put some foam strip in between the two walls. I’m sure that would improve the setup further, but at the same time, I think it’s good enough.

The one big question I have now that I’m using a mass-spring-mass system is: Would I really have needed the expensive foam? I’m wondering if I could have just used the leftover stone wool from the wall project. That would have made the whole project a lot cheaper. But nothing like some good old sunk cost fallacy to keep you going. Now that I had ordered the foam, what else was I going to do with it?

What’s next?

I did some research on the impact screen and I’m fairly decided on which one I want to get. I’ll order it soon. I also need to decide if I want to paint the walls and ceiling or just cover them in foam panels. If I do end up painting the wall, I should probably do that before I put up the screen.